Automation helps company improve production efficiency

2023-08-16

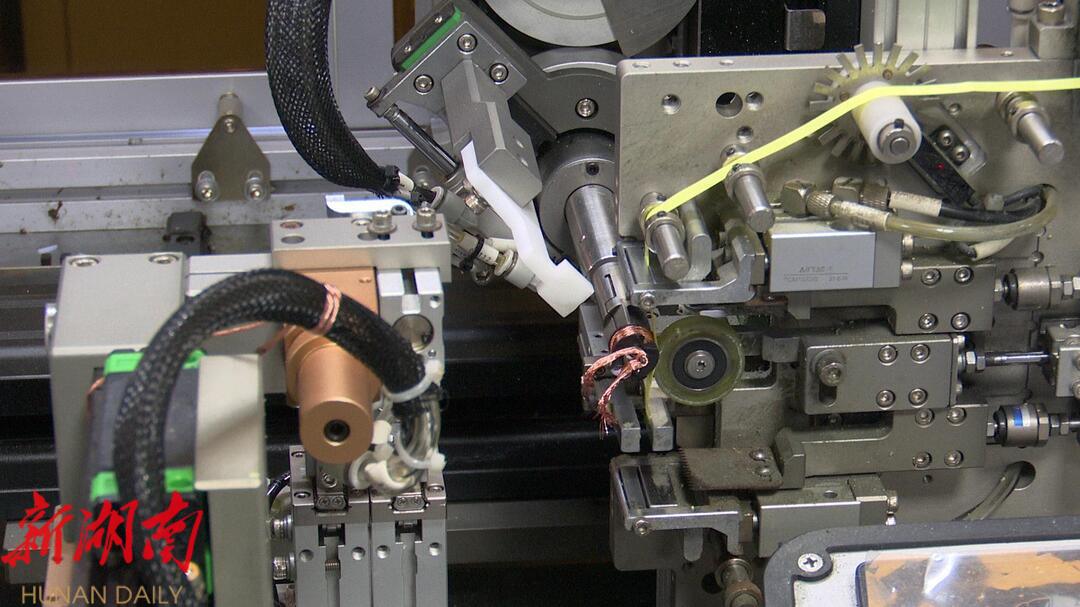

In recent years, Chenzhou Chengrui Electronics Co., Ltd. has gradually introduced advanced instruments and equipment such as high-precision automatic winding machines, automatic soldering machines, and testers, and continued efforts to optimize management to significantly improve production efficiency.

The company is a national high-tech enterprise specializing in the production of transformer components, and integrating R&D, production, sales, and services. Currently, it has more than 300 employees, as well as more than 1,600 people in its branch factories and for outsourcing. More than 5 million electronic transformers can be produced per month, which are provided for Delta Electronics, and other enterprises.

In the company’s automated production workshop, rows of neatly arranged high-precision wire winding machines are being operated. There are less than 10 workers in the workshop replacing spools and consumables, and inspecting products, which is a big difference from labor-intensive manual workshops in the past.

According to research staff, this new type of winding machine consists of single axis and multi axis models. Under the same conditions, one machine can do work equal to that of three workers, and the defect rate is greatly reduced.

Ma Haibo, manager of the R&D Department, said, “In the past three years, we have invested 5 million yuan in independent R&D and some advanced equipment, and now the company has approximately 60 sets of advanced equipment, with a daily output of approximately 50,000 high-frequency voltage transformers. The efficiency is about three times higher than before in a man-machine cooperation method.

Since 2021, the company has introduced fully automated production equipment to replace manual production and implemented refined testing and management of products to ensure quality. So far, the production of orders has been scheduled until the end of the year.

“It is expected that we will have 90 sets of automation equipment at the end of this year, and at the end of next year, there will be 180 sets of automation equipment. Based on automated equipment and professional R&D personnel, the production capacity will achieve over 50% of the company and the automated production efficiency will reach 300% of the traditional efficiency,” said Ma Haibo.

The company has also continued efforts to fulfil its social responsibility. Every year, staff are arranged to visit elderly people living alone and in need through fixed funds. Also, the company continues to participate in relevant activities of the Samaritans’ Association in the county and set up branch factories in various towns to offer more job opportunities and help villagers increase income.

It has been awarded titles such as National High-tech Enterprise, Provincial Specialized, Refined, and New “Little Giant” Enterprise, Love Enterprise, and Safe Enterprise.

Wang Guangwu, executive vice general manager of Chengrui Electronics, said, “We started to switch to automation in 2021. At the second half of 2022, we began preparations to enter into the new energy field and we will officially put new energy into production in the second half of 2023. In the coming years, new energy will take up most of the production capacity.”